NEWS CENTER

Vacuum vents is one of the several operations required to compounding polymers with additives and fillers to obtain the required physical properties. The generated granular compounds must be free of voids and residual volatiles, otherwise they may cause defects in extruded or injection molded components.

Modification companies must be aware of customers' concerns, namely single screw extruders, which typically do not have any vacuum capacity, and any volatile substances in the particles can only be released in the final components - leading to surface defects, ventss, etc. For hygroscopic polymers, effective vacuum during the modification process is crucial for maintaining physical properties.

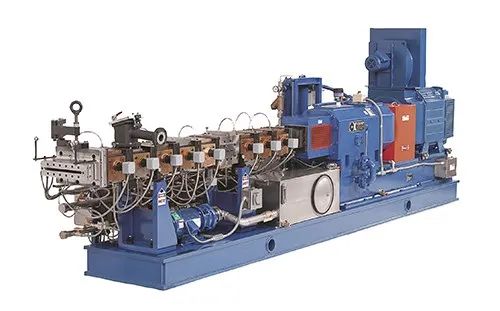

According to process requirements, the vacuum ventss in the extruder barrel can be operated under atmospheric pressure or vacuum, and the most typical mixing process includes two types of vacuum. The machine can be equipped with multiple vacuum vacuum vents to remove a large amount of gas from solvents or monomers, while generating lower levels of residual volatiles in the finished product.

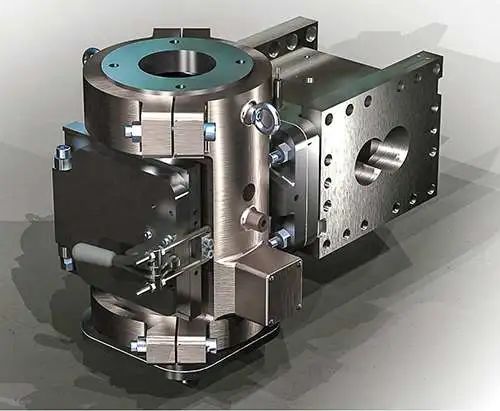

Currently, various vacuum vents designs have been developed for co rotating twin screw extruders to adapt to a wide range of applications and materials; These include vacuum plugs, extended vacuum pipes, and side vacuum vents. Each of these designs has undergone significant development to overcome some issues related to the design of standard vacuum vents located at the top of the extruder barrel.

Whether it is atmospheric or vacuum, the requirements for stable operation of the vacuum vents are the low filling degree inside the screw in the vent area and the "melting seal" (filling screw) upstream of the vacuum vents.

vacuum issues

1. Operational issues, polymer (and/or other raw materials) flowing out of the extruder vacuum vents. This process interference usually requires operator intervention to clean the vacuum vents or to shut down the production line.

2. Due to insufficient vacuum in the extruder barrel, residual volatiles/gases remain in the composite particles. In this case, it is necessary to improve vacuum efficiency to produce acceptable product quality.

Each of these problems has a unique solution, as described below.

Why does polymer come out of the extruder from vacuum vents?

This type of problem is common in all twin screw mixing extruders. The atmospheric vent is designed to vent air, moisture, and other volatile gases after the initial melting of the polymer. The velocity of air and/or steam flowing out of these vacuum ventss is a function of volumetric flow rate and vacuum vents area.

When the steam speed is too high (due to its large volume or small opening area), the discharged gas often carries solids, causing the melt to flow out of the vacuum vents. The solution here is to provide a larger vacuum area and may require additional vacuum ventss to achieve this.

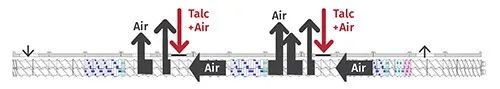

Particle fillers (such as talc powder, mineral fillers, CaCO3, etc.) need to pass through the vacuum vents when feeding from the downstream side to the molten polymer. These vacuum ventss are designed to release air entering the machine through side feeders with powder. The lower the packing density of the filler, the more air enters the extruder barrel and must be discharged. If the opening area of the ventilation hole is too small (relative to the volume of air that must be discharged), the resulting high outlet velocity often carries fine powder and powder out of the ventilation hole. Solving this problem requires expanding the vacuum area, as mentioned earlier, and may also require additional vacuum ventss.

The presence of unmelted polymer at the first side feeder also causes the filler to come out of the atmospheric discharge vents associated with that side feeder. To diagnose whether this is related to the vacuum vents, a physical inspection of the melt quality at the side feed vents is necessary to verify the presence of any unmelted resin. If this is the case, the solution requires modifying the screw design upstream of the screw (polymer melting point).

In the case of high filling (up to 80%) and high productivity, lateral feeding of low bulk density fillers requires multiple atmospheric vents to promote the removal of a large amount of air from the barrel.

Why doesn't the thing that should be discharged come out?

If the current machine configuration, vent design, and operating conditions are unable to remove a sufficient amount of volatile matter, these solutions typically require modifications to the screw design and/or barrel configuration.

The removal of volatile gases from the melt is achieved through vacuum, providing additional driving force for mass transfer. Most composite production lines operate under vacuum pressure within the range of 20 to 27 inches of mercury (approximately 100-300 millipascals). There are many available solutions that can further improve the devolatilization rate:

If the residence time of the melt under vacuum is a limiting factor (diffusion limitation), one option is to reduce production to increase the average residence time. This is not a popular option, but it is the easiest to implement.

Another solution to increase residence time requires repositioning the melt sealing element further upstream in the barrel. The vacuum extends further upstream as a result.

Increase the vacuum to maximum - this usually requires replacing the existing vacuum pump system.

Reduce the filling degree of the vacuum section by increasing the spacing between conveying elements. The lower filling material in the screw channel produces a thinner melt layer, through which gas must diffuse.

Reconfigure the machine with additional vacuum vents. This may require extending the current screw length to add additional vacuum vacuum vents (if the L/D of the existing screw is not sufficient to include a second vacuum vacuum funnel).

Inject a stripping agent (usually water) into the barrel upstream of the vacuum vacuum vents to reduce the partial pressure of volatile substances.

Nanjing Kunwei Lansheng Extrusion Intelligent Equipment Co., LTD

Address: No. 9 Guangtai Road, Dujiangyan City, Chengdu City, Sichuan Province

45 Limao Road, Wujin District, Changzhou City, Jiangsu Province

Tel:400-096-8228

E-mail:sales@njkwls.com